Integrated Microfluidic Manufacturing: R2R, Injection Molding, and Content Loading Solutions

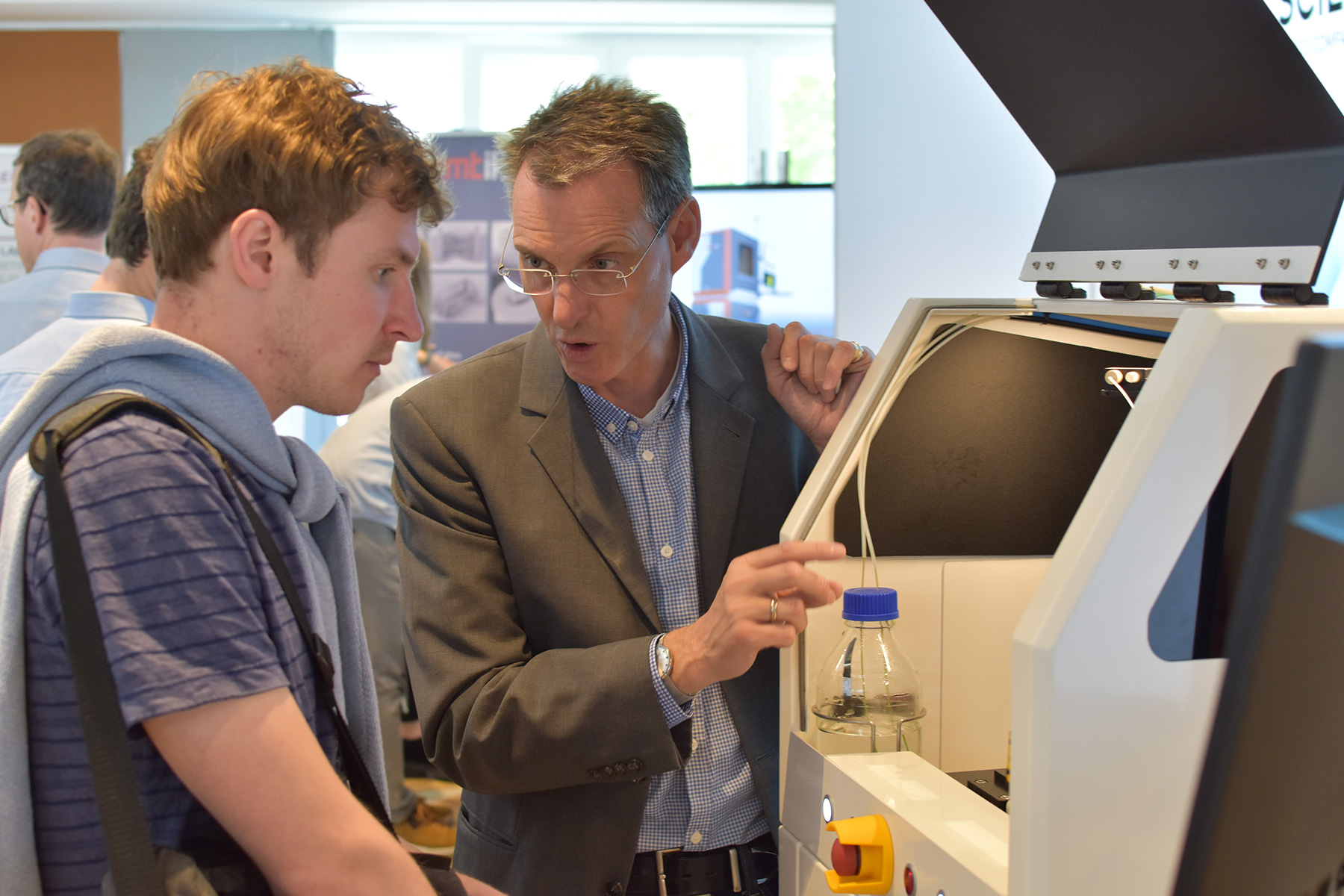

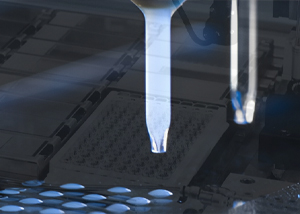

In this workshop, we explore the convergence of roll-to-roll (R2R) processing and injection molding technologies, highlighting their combined potential in advancing microfluidic consumable manufacturing. Beyond the core fabrication methods, the discussion will also address critical post-processing steps such as surface chemistry modification and content loading via dispensing technologies. We will showcase real-world product examples developed at STRATEC Consumables, in collaboration with KURZ as our manufacturing partner for roll-to-roll processing. By examining these synergies, we aim to highlight pathways toward scalable, cost-effective production of next-generation microfluidic systems.